Magazine

Design incorporates objects, people,

ideas based on the small pleasures of everyday life.

Meet your Beautiful design world with the DDP Design Fair.

-

LAMP

COLLABORATION/PAPER POP+StoxlMono-Poly is a stool and lighting object designed around the concept of translating brutalist architecture into furniture. Comprised of eight stools, Mono-Poly stacks vertically around a center located LED stand, maximizing space efficiency when not in use. The stools' geometric yet simple structure allows for versatile configurations and arrangements. When stacked, the gaps between the stool legs create a linear light effect in the surrounding area.MAKER PAPER POPWhen creating paper furniture, the initial focus is typically on functionality, followed by refinement of the design. However, through this collaboration with the designer team, we adopted a new approach to product development. We started with the aesthetic design, aiming to preserve its integrity while ensuring the product's durability and functionality. This approach presented an exciting and innovative challenge from a manufacturing perspective.DESIGNER StoxlThe workshop is surrounded by paper and packaging companies, which sparked an interest in developing products using paper and corrugated materials. Designing furniture from paper requires careful consideration of its structural integrity, and we benefited greatly from the expertise of PAPER POP, who have a deep understanding of the material's properties. This collaboration allowed us to enhance the stool's functionality. Additionally, the use of a black matte vinyl sheet, a finish not previously employed by PAPER POP, contributed to a successful outcome.

2024-12-0360 -

FURNITURE

COLLABORATION/Doodd+Flyingfish StudioKraftobjet is a brand that uses its own developed paper pipes as the primary material, combining them with various eco-friendly materials to create home accessories and furniture. Made from 100% recycled kraft paper, the paper pipes are coated with water-soluble coatings and printed with eco-friendly ink, forming the foundation for a range of sustainable products. The brand focuses on discovering new possibilities in materials and enhancing their value. The modular shelf is designed to incorporate paper pipes as a key part of the furniture, pairing them with aluminum profiles to ensure both eco-friendliness and durability. The joint blocks and brackets that connect the paper pipes and profiles are engineered for efficient assembly and disassembly using the brand’s own technology. The side table, built with a large paper tube as the base, features a detachable top for internal storage. It can also function as a stool when a cushion is added, offering versatile use with an optimized size.MAKER DooddDoodd and Kraftobjet, known for their traditionally rigid and static designs due to the nature of their respective industries, found new creative direction through their collaboration with designer Hyunah Lee of Flyingfish Studio. This partnership brought fresh ideas, concepts, hand-drawn graphics, and craftsmanship infused with passion, offering a new perspective on furniture design from a designer with a background in fashion.DESIGNER Flyingfish StudioCollaborating with the manufacturer has been a great opportunity to expand the design scope. By sharing information and discussing ideas, both the designer and the manufacturer were able to create great synergies. It was truly rewarding to create a superior product through collaboration, one that surpassed what we could have achieved working as an individual brand.

2024-12-0356 -

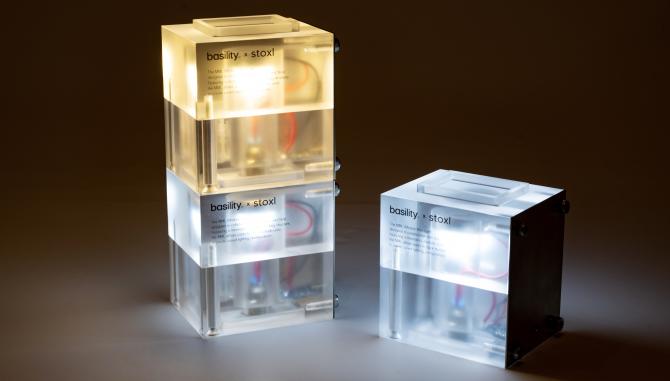

LAMP

COLLABORATION/TRIPLE H+StoxlThe MML(Module Mini Light) is a modular lighting system inspired by the BS series of stackable modular shelves used in manufacturing companies. The MML features a modular design with interlocking grooves on its top and bottom, allowing units to be stacked securely. With its minimalistic and intuitive form, the MML is designed on a scale suitable for desk décor, making it easy to stack multiple units to create various lighting configurations. When used as a single light, its cube design allows for flexible placement in any direction, giving users complete freedom to position it according to their preference.MAKER TRIPLE HI found great interest in solving problems through collaboration with the designers. While I have previously developed products from a manufacturing perspective, this collaboration allowed me to explore different materials from a designer’s viewpoint and think about how to transform a product into a work of art. In particular, a lot of research went into integrating Basility’s BS modular shelf structure into the lighting design. We used technologies and materials such as 3D printing, MCT machines, and acrylic to achieve the highest quality using transparent materials. These processes were made possible through collaboration with the designer, and this experience made the design process more enjoyable and meaningful.DESIGNER StoxlThe collaboration between different manufacturing companies and design teams was a highly valuable experience, allowing us to successfully complete the project by exchanging the various resources each party contributed. It also provided an opportunity to enhance my problem-solving skills at every stage of the design process, while highlighting the importance of effective communication. Overall, it was a great opportunity to gain insights into both design details and the design approach for mass production.

2024-12-0357 -

Daily supplies

COLLABORATION/3D MAKERS+StoxlMosscape is a modular moss planter made from PLA using FDM (Fused Deposition Modeling) 3D printing technology. The base adopts a regular hexagonal shape, featuring triangular grid compartments that provide dedicated spaces for moss to grow. Each compartment has perforated bottoms, allowing moss to anchor its roots securely and absorb moisture through evaporation. Through parametric design, Mosscape offers various surface inclinations resembling natural terrains, creating diverse volumes when assembled. The use of biodegradable PLA, which leaves no microplastics, underscores the product's eco-friendly nature. Combined with the aesthetic appeal of terrarium-inspired designs commonly used for desk décor, Mosscape highlights both sustainability and style. The panel-based modular structure extends its utility beyond simple desktop decoration, making it suitable for a variety of interior design applications. Moreover, leveraging 3D printing technology eliminates the need for molds, enabling on-demand production and adding a significant competitive edge.MAKER 3D MAKERSFrom the manufacturing perspective, this project was meaningful as it involved overcoming challenges that are often hard to resolve. This was made possible through effective communication and collaboration with the designers. I hope we can continue to showcase more creative and innovative products using 3D printing technology. DESIGNER StoxlThis project provided a valuable opportunity to reflect on how to secure a competitive edge in the emerging 3D printing market, which uses different materials and manufacturing methods compared to conventional production. I had previously worked with PLA lighting products and had developed my own expertise in 3D printing. I believe this pre-existing understanding of 3D printing led to a better collaboration with 3D MAKERS and ultimately to a better outcome. It was a great opportunity as a designer to learn which aspects of product competitiveness and mass production are most important to the manufacturer.

2024-12-0354 -

FURNITURE

COLLABORATION/CAMFURSLINE+STUDIO PESIThe DAILY L2 and DAILY STOOL are part of a new line within the DAILY COLLECTION, designed for the lifestyle brand LIKE THIS. Reflecting on the brand's philosophy of encouraging a mindful life, these pieces were created to offer practical yet unique furniture that seamlessly integrates into any setting. With their minimalist design, the DAILY L2 and DAILY STOOL complement a wide range ofenvironments, delivering an unexpectedly high level of comfort and elevating the daily experience. These versatile pieces effortlessly blend into daily life, making them ideal not just for homes, but also for public spaces like restaurants, educational institutions, and offices.MAKER CAMFURSLINEWe collaborated with Studio PESI, known for its simple, modern, and distinctive designs, to develop a podium that stands apart from traditional, heavy styles. The product was designed to achieve balance between aesthetic appeal, durability, and quality, making it suitable for mass production. The packaging was thoughtfully engineered for flat-pack shipping, enhancing practicality and efficiency.Crafting a design that is both simple and unique posed significant challenges. However, the designer’s extensive experience and expertise provided clear guidance throughout the process. Their adaptability and prompt feedback were instrumental in achieving an exceptional final product. This fair presented an opportunity to explore many intriguing items, and should the opportunity arise, we look forward to collaborating with a diverse range of designers again in the future.DESIGNER STUDIO PESIBreaking away from conventional podium designs in the current market required a thorough and collaborative decision-making process. Through continuous deliberation and review, we successfully determined the optimal approach for the product. Each team member gave their utmost effort in their respective roles, enabling us to achieve an exceptional level of quality despite the project's tight timeline.

2024-12-0352 -

FURNITURE

COLLABORATION/TRIPLE H+TGC_FGWe developed a modular hanger system tailored to both B2B and B2C business models. Designed with emphasis on portability, manufacturability, ease of assembly, and expandability, the system supports a business model that allows for rental or sale in pop-ups, exhibitions, and clothing stores.The rotating angled hook module provides versatile storage options, enabling different configurations to accommodate a wider variety of items. Standardized screw thread specifications make it easy to attach additional modules at the front or back, meeting the needs of both home users and retail environments. For pop-ups or stores, long bar modules can be added, offering adaptable solutions for various spaces.MAKER TRIPLE HIt was truly a rewarding experience to engage in a strong design process while collaborating with the designers. From the very beginning of the development phase, we were able to clearly define the direction of the design and establish a solid product concept, which helped the development proceed smoothly. The collaboration with the designer for the coat rack design process was a very meaningful experience. The 'Nemo Module Rack' features a modern and minimalist design, crafted from stainless steel with a polished finish. After several discussions with the designers, we were able to develop a product that considered not only office and home use but also expanded its use for pop-ups and showrooms. The designer’s creative input really unlocked a range of possibilities for the product, and the manufacturing process helped bring these ideas to life with enhanced quality and precision.DESIGNER TGC_FGHaving primarily worked with electronics, I was accustomed to materials like plastic and resin, but this project allowed me to gain a wealth of new experiences working with clay. I learned about different aspects of clay, such as its viscosity, composition, and the types of glazes used, depending on the country of origin. The manufacturers provided clear production standards.There were many moments of reflection as I considered how to blend the unique beauty of clay with the modern world. Through careful craftsmanship and collaboration with skilled manufacturers, we were able to create a new direction for ceramic products.

2024-12-0354 -

Daily supplies

COLLABORATION/Limjaehee Ceramics+DodThe Leaf Bowl was inspired by the shapes and phenomena found in nature. When reflecting on the purpose and origins of bowls, it’s interesting to note that, in the past, leaves were often used to wrap and store food, serving a similar function to that of a bowl. By observing the curves of leaves and petals, I simplified their soft shapes and stems to create the design.Additionally, inspired by how leaves and petals tremble in the wind, I incorporated a sensory element into the bowl, so that when food is placed inside, the bowl subtly vibrates. When plating liquid dishes, the escaping juice follows the shape of the stem, creating new colors and patterns on the bowl.MAKER Limjaehee CeramicsExploring the form of bowls from a fresh perspective was an incredibly rewarding experience. Collaborating with a designer who has a deep understanding of clay’s diverse finishing techniques and structural limitations sparked engaging discussions and creative ideas. To achieve the vibrating effect and deliver a high-quality product, we challenged traditional manufacturing methods and embraced a new approach. The process of finding the perfect balance between usability, manufacturability, and design was both exciting and enriching.DESIGNER DodHaving primarily worked with electronics, I was accustomed to materials like plastic and resin. However, this project offered an entirely new experience with clay. The manufacturing team provided invaluable insight on the different approaches to handling clay across countries, covering aspects such as viscosity, composition, glaze types, and production standards, while allowing me the creative freedom to explore new designs.The process involved deep reflection on how to adapt the timeless beauty of clay to suit the modern era. By collaborating with a manufacturer renowned for their precision and craftsmanship, we were able to create a ceramic product that pushes the boundaries of innovation.

2024-12-0350 -

Daily supplies

COLLABORATION/Himalaya store+olmang & ddudduThe design, originally based on a traditional wooden box, has been updated to improve its marketability by incorporating a light maple wood accent. This wooden box showcases unique patterns that can only be achieved through CNC machining. With minimal handcrafting, the result maximizes production efficiency, offering greater time and cost-effectiveness compared to other wooden box products.MAKER Himalaya storeEnsuring the accuracy of the pattern during production was a challenging task. However, with the designer’s guidance and many rounds of trial and error, we were able to resolve the issue. Through mass production, we aim to create a practical product that is useful and accessible to everyone. The project progressed with consistent feedback on the prototype’s proportions and production feasibility. Together with the designer, we worked with passion and commitment to bring this product to life.DESIGNER olmang & ddudduIt was a great experience to take on a new project. By working with a manufacturing company that has a wide range of expertise and experience, we were able to collaborate smoothly. We had many discussions and received feedback throughout the process, and I feel that the results turned out better than when I worked alone.

2024-12-0341